all your manufacturing needs

Ready to use factory maintenance software

CMMS Software Development Company in Chennai

Computerized Machine management System (CMMS) is a lucrative software that smartly manages entire production-related data, and plans the maintenance schedules that improve manufacturing quality and decimates downtime.

We at iStudio Technologies, provide proactive CMMS software in Chennai, India, that completely transforms your stereotypical plant maintenance activities to the digital platform and enhances productivity up to 40%.

Features of Factory Maintenance

Software

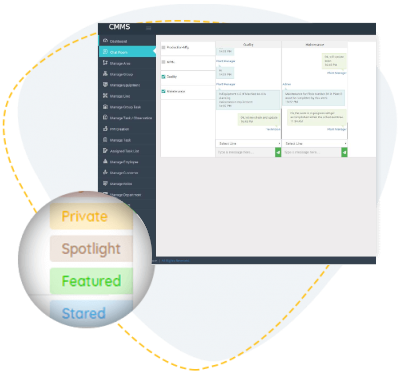

Asset management

Access the complete details of every asset from your fingertip by implementing our advanced plant maintenance software. CMMS helps the management or even the maintenance workers to get to know the entire details of a particular asset to carry out planned maintenance activities.

Work Order Management

Assign work order to your human resource without any disruption by making complete use of our plant maintenance software, the CMMS software we provide helps the management to know the engaged machine in maintains and plan the work allocation accordingly.

Preventive Maintenance

Make your regularly scheduled maintenance plan more meaningful with our impressive CMMS software plant maintenance now made completely effective and out of traditional approach with the help of factory maintenance software that avoids unnecessary production downtime, manufacturing slowdown and irregular maintenance activities.

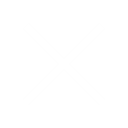

Communication Platform

A highly interactive platform that helps workers from different hierarchy verticals to engage in productive conversation and carry out un-disruptive production. The communication platform also plays a pivotal role in clarifying the technical difficulties faced by a fresh worker with their respective senior experts.

Equipment Health Monitoring

Tracking the health-wellness of machines is still a challenge in the manufacturing industry that leads to the improper maintenance schedule. We provide intelligent plant maintenance software that keeps tracking machines health condition and updates the operator on a timely basis, to fix proper maintenance activities.

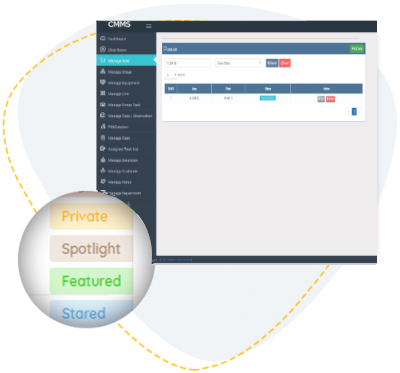

Data Visualization

A prolific analytical wing of our factory management software, that drives the entire CMMS based maintenance process of the entire plant, by delivering detailed insights on currently available assets and also predicts the future requirements on asset buying.

Predictive Maintenance

We take forward the entire maintenance activity of your plant by deploying cutting-edge deep learning technology that schedules maintenance based on prediction basis. Unlike the stereotypical preventive maintenance, predictive maintenance will give priority to machines that need care instead of a serial priority.

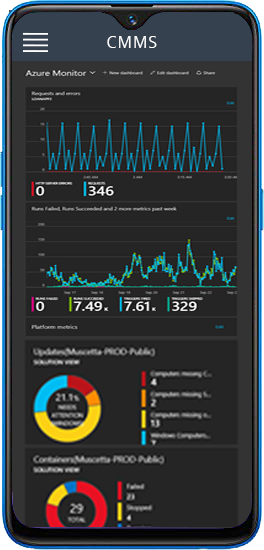

Mobile app

Maintenance assistance and dispute handling guidance have now become portable with our enhanced mobility solutions for plant maintenance. We provide the best mobile app services that deliver great catalytic support for the efficient operation of the entire plant.

IoT Integration

The inch by inch monitoring of every device in the manufacturing unit is made possible with the implementation of IoT devices. The IoT devices send instant notification on any critical conditions faced by a machine to the concerned technician's mobile app who got integrated.

AI/ML

Artificial Intelligence plays a pivotal role in the success of CMMS software by deploying continuous monitoring and self-maintenance processes. Continuous monitoring prevents unexpected downtime and slow turnaround time by learning from mistakes and improper approach, whereas self-maintenance enables self-treatment done by machines where humans are not readily available to fix the issues.

Root Cause Analysis

An essential integral part of CMMS software, that helps to find the core reason behind the defect of the material. The CMMS software we create holds the complete data of equipment, and it allows the sensor to analyse the entire data and figure out the core reason for the downfall.

Merits of Factory Maintenance Software

- Plant maintenance software helps to carryout a well-planned scheduled maintenance process.

- Factory maintenance software we provide helps you in proper work allocation and timely completion of tasks.

- Helps in keep a check on the available inventory and maintains a perfect balance in the turnaround of stocks.

- Implementation of plant management software helps you to completely eliminate the stereotypical paper work on maintenance.

- Adopting a well crafted CMMS software would increase your manufacturing plant’s productivity upto 40%.

- CMMs deployment ensures structured maintenance practice, hence it gradually reduces the downtime and spending on repairs.

- Fixing IoT sensors around your plants not just intimate the health status of equipments instead, it also ensures workers safety.

- Having a plant maintenance software aside would eventually increases your ROI and reduces overtime working.

Our Out-Of-Box CMMS Solutions From IStudio Technologies

Human-friendly Dashboard

Benefits

- Gives management a clear bird’s view on equipment maintenance status

- Real-time update of maintenance status in no time

- Helps manufacturing team to easily compare planned vs actual periodic maintenance task

Communication Platform

Benefits

- Informed work progress

- On-time doubt clearance

- Zero documentation and efficient production time management

Equipment Health Monitoring

Our self-automated CMMS software tracks the health condition of equipment in its life journey and schedules the preventive maintenance regularly without manual assistance.

Benefits

- Pre-defect prediction leads to prolonged sustainability of machines

- Avoids unnecessary maintenance work which interrupts production activities

- Optimized investment over human resource and equipemnts.

Predictive Maintenance

Benefits

- Pre-defect prediction leads to prolonged sustainability of machines

- Avoids unnecessary maintenance work which interrupts production activities

- Optimized investment over human resource and equipemnts.

- Provides predicted inspection time and estimates lifespan of your assets.

Data Visualization

Benefits

- Maintenance scheduling made easy with floor-wise integration of data visualization approach.

- Advanced map navigates technician to the right machine at rigth time

- Overall maintenance report helps purchase team to make better decision on acquiring inventories

- Helps to carry out deep-rooted data exploration over past equipment failure and maintenance activities

Our End-To-End CMMS Services

Why Choose Us

Getting To Know About CMMS

What is CMMS?

Computerised Maintenance Management System or Enterprise Asset Management system is an approach of handling your production equipment and machinery in an efficacious way by monitoring its operation in a 360-degree viewpoint and helps to enhance their productivity.

This system has got transformed from manual deployment to systemised implementation, and now everything gets automated when it comes to handling the production assets. Despite the industry, this process can be deployed anywhere to improvise overall productive of the entire system in a customised execution method.

This solution mostly gets coordinated with manufacturing businesses where the maintenance, facilities and operational department handles the process. A CMMS solution is helpful in various aspects like:

- Processing work orders and work requests

- Scheduling preventive maintenance tasks

- Handling inventory and spare parts

- Performing condition monitoring

Benefits

- Ensured asset longevity

- Surpass quality standards

- Transparent working procedure

- Reduce in time of work completion

- Zero manual error

- Decrease in maintenance cost

- Enhances worker productivity

- Automation in decision-making

- Completley systemized execution

- Increased equipment uptime

How CMMS Works

Who can use CMMS

CMMS Benefits We Deliver